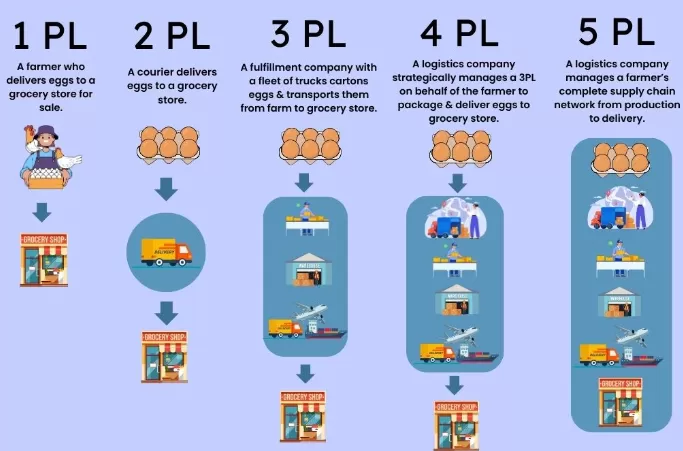

Let's be honest. The world of logistics is drowning in acronyms and complex terminology. But here’s the secret: understanding the fundamental difference between 1PL, 2PL, 3PL, and 4PL isn’t about memorizing definitions. It’s about strategy.

Choosing the right model is one of the most critical decisions a business can make. Get it right, and you unlock scalability, resilience, and a powerful competitive advantage. Get it wrong, and you’re shackled by hidden costs, operational rigidity, and stunted growth.

This guide is designed to be your strategic compass. We’ll move beyond textbook explanations into the real-world mechanics of how products move, who controls them, and how you can architect a supply chain that doesn't just support your business—it accelerates it.

The Foundation: What Does ‘Party Logistics’ Really Mean?

Before we dive in, let's demystify the term. The "PL" stands for "Party Logistics." The "Party" refers to the key actor responsible for executing and managing the movement of goods.

Think of it not as a social gathering, but as a legal and operational term. The number (1st, 2nd, 3rd, 4th) indicates how many degrees of separation exist between the owner of the goods and the executor of the logistics activity.

It’s a spectrum. On one end, you have total internal control (1PL). On the other, you have complete external orchestration (4PL/5PL). Your goal is to find your optimal point on that spectrum.

Deconstructing The Models: From Self-Reliance to Full Outsourcing

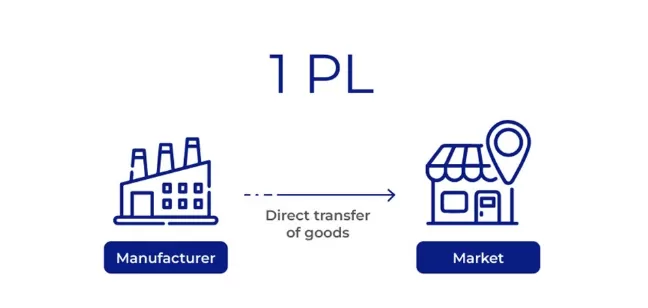

1PL - First-Party Logistics: The Self-Sufficient Model

The Core Definition: A 1PL is the manufacturer or seller itself, using its own internal assets and resources to manage its entire logistics operation. This is the definition of vertical integration in logistics.

How It Works in Practice: The company owns or leases its warehouses, manages its own inventory, and operates its own fleet of trucks or ships for domestic and international routes. The entire process, from the warehouse shelf to the customer's door, is handled by employees on the company's payroll.

Real-World Example:

The Classic: A local farmer who uses their own truck to deliver produce to a nearby market.

The Titan: Amazon. This is the most sophisticated 1PL operation on the planet. Amazon owns a vast network of fulfillment centers, a massive private fleet of trucks and planes, and employs thousands of drivers. They control virtually every millimeter of the supply chain for their own inventory, which is why they can promise and deliver mind-boggling speed.

The Bottom Line:

Advantages: Maximum control, brand consistency, and direct oversight of the customer experience.

Disadvantages: Astronomically high capital expenditure (CapEx), significant operational complexity, and limited geographic flexibility.

Ideal For: Giant corporations with immense, predictable volume and the capital to build a world-class logistics arm.

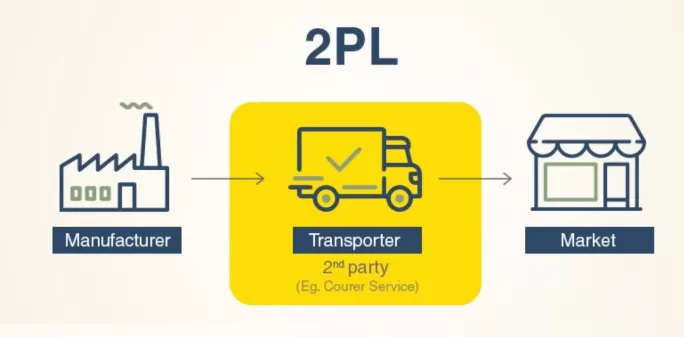

2PL - Second-Party Logistics: The Asset-Based Specialist

The Core Definition: A 2PL is an asset-based carrier that provides a specific, point-to-point transportation service. They are the "feet on the street" of logistics.

How It Works in Practice: A 2PL owns the assets needed for a specific leg of the journey—ships, airplanes, trucks, or rail cars. Their core business is selling space on these assets to move goods from A to B. They are experts in transportation, but not in overall supply chain management.

Real-World Example:

Ocean Freight: Maersk. They own the container ships.

Air Freight: DHL Express. They own the aircraft and the express delivery network.

Trucking: J.B. Hunt. They own the trucks.

You, the shipper, are responsible for hiring multiple 2PLs (like a freight forwarder for China routes) and coordinating between them—a complex and time-consuming task.

The Bottom Line:

Advantages: Deep expertise in a specific mode of transport, massive scale economies in their niche.

Disadvantages: You manage the complexity. You hire the ocean carrier, the drayage trucker, the warehouse—and ensure they all talk to each other. The risk of delays and miscommunication is on you.

Ideal For: Businesses that need to move large volumes between fixed points and have the internal logistics team to manage the coordination.

3PL - Third-Party Logistics: The Outsourced Operator

The Core Definition: A 3PL is an external company you hire to outsource a wide range of your logistics operations. They are the integrators, often leveraging the assets of 2PLs but adding a layer of management and value-added services.

How It Works in Practice: A 3PL provides a bundle of services that typically includes transportation, warehousing, pick and pack, cross-docking, and freight forwarding. They have contracts with carriers (2PLs) managing everything from door-to-door shipping and use their own Warehouse Management Systems (WMS) to execute your operations. You get a single point of contact for multiple services.

Real-World Example:

An emerging DTC (Direct-to-Consumer) eyewear brand uses a 3PL like ShipBob or Flexport. The brand's inventory is stored in the 3PL's warehouse. When an order comes in from Shopify, Amazon, or their own website, the 3PL's software receives the order, their staff picks and packs the glasses into a custom-branded box, and they hand it off to a carrier (like USPS, UPS, or DHL) for the final mile delivery. The brand owner sees the entire process in a dashboard.

The Bottom Line:

Advantages: Scalability without massive CapEx, access to expertise and technology, focus on core business (marketing, product development), and often improved cost efficiency.

Disadvantages: Less direct control, potential for your brand experience to become "generic" if not managed carefully, and the need to vet partners thoroughly.

Ideal For: The vast majority of growing e-commerce businesses, SMEs, and any company looking to scale operations without building their own infrastructure.

4PL - Fourth-Party Logistics: The Supply Chain Architect

The Core Definition: A 4PL is a non-asset-based strategic partner that manages and orchestrates your entire supply chain. They don't own trucks or warehouses; they own the intellectual capital and technology to design and optimize the entire system.

How It Works in Practice: The 4PL acts as a single strategic interface between you and a multitude of service providers (3PLs, 2PLs, warehouses, customs brokers). They select the partners, negotiate contracts including Incoterms like DAP and DDP, implement technology platforms for end-to-end visibility, and continuously analyze data to optimize for cost, speed, and resilience. If a 3PL is a contractor, a 4PL is the architect and general contractor combined.

Real-World Example:

A multinational automotive company hires a firm like Accenture or DHL Supply Chain in a 4PL capacity. The 4PL designs the entire supply network: they might choose one 3PL for warehousing in Europe, a different one in North America (e.g., at a port like Los Angeles), negotiate rates with multiple ocean and air carriers (2PLs) for shipping from China to various US hubs, and implement a control tower software that gives the automotive company a single pane of glass to view its global operations in real-time.

The Bottom Line:

Advantages: Holistic optimization, data-driven strategic management, access to best-in-class partners, and ultimate flexibility.

Disadvantages: Highest cost model, most complex to implement, requires a deep level of trust and transparency.

Ideal For: Large enterprises with complex, global supply chains where logistics is a core strategic function, not just a cost center.

The Frontier: What is a 5PL? (The Tech-Driven Ecosystem Orchestrator)

Let's be clear: 5PL is not yet a universally standardized term. However, it's emerging to describe a provider that focuses on leveraging advanced technology like AI, machine learning, and blockchain to optimize logistics ecosystems for multiple clients simultaneously.

The Core Idea: A 5PL aggregates demand from many clients, potentially filling entire 40ft containers, to achieve unprecedented economies of scale and uses predictive analytics to dynamically route freight, manage inventory across networks, and create self-optimizing supply chains. They are the true "brains" of the operation.

The Ultimate Comparison: 1PL vs. 2PL vs. 3PL vs. 4PL

| Feature |

1PL |

2PL |

3PL |

4PL |

| Core Role |

Operator |

Asset Specialist |

Operator & Integrator |

Architect & Orchestrator |

| Asset Ownership |

Yes |

Yes |

Sometimes (Warehouses) |

No (Leverages Partners) |

| Scope of Services |

Entirely Internal |

Single Mode Transport |

Multiple Logistics Functions |

End-to-End Supply Chain |

| Value Proposition |

Total Control |

Point-to-Point Movement |

Operational Efficiency & Scalability |

Strategic Optimization |

| Cost Model |

High Capital Expenditure |

Pay per Service |

Variable Operational Cost |

Management Fee + Performance |

| Best For |

Giants like Amazon |

Companies with internal logistics teams |

Growing E-commerce & SMEs |

Large, Complex Enterprises |

How to Choose: A 5-Step Framework for Your Business

This is where theory meets practice. Ask yourself:

What are our core competencies? Are we product innovators and marketers? Or are we also logistics experts? Be honest. Your answer likely rules out 1PL.

What is our growth trajectory? A 2PL might work now, but will it in 12 months? 3PLs are built for scale.

How complex are our needs? Do we ship B2C parcels domestically, or do we manage international B2B shipments that require navigating customs inspections? Complexity demands a 3PL or 4PL.

What is our tolerance for management? Do we have a team to manage multiple 2PL vendors? If not, you need the single point of contact a 3PL/4PL provides.

Is logistics a cost center or a strategic advantage? If it's the latter, you're thinking like a 4PL candidate.

The Right Partner Changes Everything

Understanding these models is the first step. The next is execution. Whether you're a burgeoning brand needing the scalable muscle of a 3PL or an established enterprise seeking the strategic insight of a 4PL approach, the choice of partner is everything.

The best providers don't just execute tasks; they provide clarity, predictability, and a genuine partnership.

Ready to architect a supply chain that's a competitive advantage, not a costly headache?

Schedule a Free Supply Chain Review with our experts. We'll analyze your current operations and goals to help you identify the perfect model.

Frequently Asked Questions (FAQs)

1. Q: We're a small business. Is it possible to use a combination of these models, or do we have to choose just one?

A: Absolutely. Most businesses operate a hybrid model. It's very common to use a 3PL for your e-commerce fulfillment while simultaneously negotiating directly with a 2PL (like a trucking company) for bulk raw material shipments to your factory. The key is to clearly define which partner is responsible for which segment to avoid confusion and accountability gaps.

2. Q: How long does it typically take to transition from a 2PL/self-managed model to a 3PL?

A: A well-executed transition usually takes 4-8 weeks. This isn't just about moving boxes. It involves integration (connecting your sales channels to their WMS), process mapping, shipping them your inventory, and thorough testing. Rushing this process is a recipe for misplaced stock and messed-up orders. A good 3PL will have a detailed project plan for this.

3. Q: From a cost perspective, when does it stop making sense to be a 1PL and start making sense to explore a 3PL?

A: The trigger is rarely revenue alone. Look for these signs: your logistics team is constantly firefighting instead of strategizing, you're missing delivery promises because you're geographically constrained, or you're facing a major capital outlay for new warehouse space or trucks. When operational overhead starts to stifle growth, it's time to look at a 3PL.

4. Q: What's the single biggest point of failure when working with a 3PL?

A: Poor communication, without a doubt. It's not usually a catastrophic shipping error. Failure stems from unclear SLAs (Service Level Agreements), not having a dedicated account manager for escalation, and assuming the 3PL understands your brand's nuances without explicit instruction. Treat them as a partner, not just a vendor, and over-communicate.

5. Q: For a 4PL, what does the "technology platform" they provide actually look like?

A: Think of it as a supply chain control tower. It's a single login dashboard that gives you real-time visibility into everything: inventory levels across multiple 3PL warehouses, the status of every shipment (ocean, air, truck), landed cost calculations, and performance analytics across all your partners. The 4PL's value is making sense of all that data for you.

6. Q: We're considering a 3PL, but we have unique kitting and packaging requirements. Is that a deal-breaker?

A: Not at all. Most sophisticated 3PLs specialize in value-added services (VAS). This includes everything from building custom "kits" (e.g., bundling a shampoo and conditioner into a gift set) to inserting promotional materials and using custom-branded packaging. The key is to thoroughly vet partners and discuss these requirements upfront during the sales process to ensure they can accommodate them and price accordingly.

7. Q: How does liability and insurance work when a 3PL is handling our inventory?

A: This is a critical question. A reputable 3PL will have cargo insurance and liability coverage for goods in their care, custody, and control (C&C). However, the limits and terms vary massively. You must review their certificate of insurance and understand what is covered (e.g., fire, flood, theft) and what might be excluded. Many businesses choose to supplement with their own insurance policy for full protection.

8. Q: Is the concept of a 5PL just a marketing gimmick for tech-heavy 4PLs?

A: Right now, it's more of an evolutionary concept than a standardized model. The term "5PL" is trying to put a name on the shift towards AI-driven, predictive optimization that looks across multiple clients' data to find efficiencies no single company could see on its own. While some providers use it as a buzzword, the core idea—ecosystem-level optimization through advanced tech—is very real.

9. Q: If we start with a 3PL, can we evolve into a 4PL relationship with the same provider?

A: It's possible but not automatic. Some large logistics companies have both 3PL and 4PL divisions. However, the mindset and contract are fundamentally different. A 3PL relationship is transactional (you pay for services rendered). A 4PL relationship is strategic (you pay for management and optimization). You'd need to formally renegotiate the scope of work and commercial agreement to make that shift.

10. Q: Beyond cost, what's the most compelling reason for an established company to switch from a 2PL to a 3PL/4PL model?

A: Risk mitigation. Managing multiple 2PL contracts yourself means you bear the full risk if one carrier fails, goes bankrupt, or has a major service disruption. A 3PL or 4PL mitigates that risk for you. They have a diversified portfolio of carriers and can instantly pivot your shipments to another provider if something goes wrong, often without you even knowing there was an issue. That resilience is invaluable.

EN

EN

FR

FR

ES

ES

JA

JA

PT

PT

RU

RU

AR

AR